Sustainability

Sustainability

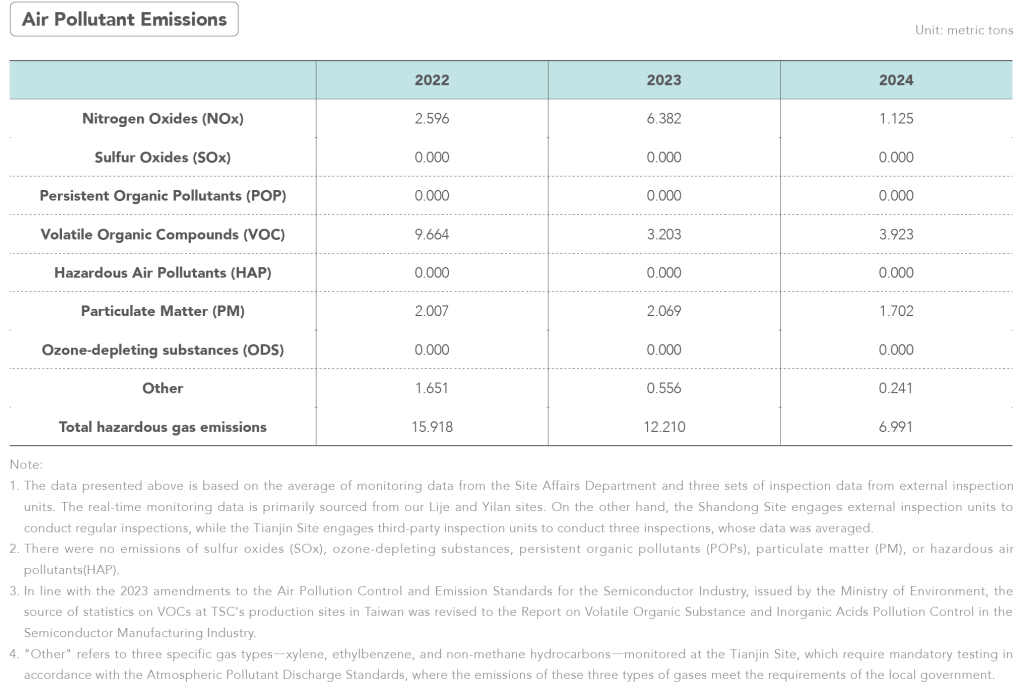

Air Pollution Prevention and Control

TSC is committed to air pollution prevention and environmental protection. All of our production sites comply with local environmental laws and regulations and undergo regular gas testing. The primary types of gases generated in the production process at our production sites include acid waste gas and volatile organic compounds (VOCs). In addition, a small amount of flue gas is emitted from the solid crystal welding process, which is treated by the acid-alkali scrubbers, ionization decomposition, fume filtration, and VOCs adsorption treatment systems, while a third-party inspection organization is commissioned to conduct regular inspections to ensure that the emission standards are met. Due to differences in the nature of wafer fabrication and assembly/testing processes at each plant, the types of air pollutants generated vary slightly.

In 2024, all of TSC’s production sites complied with local environmental regulations, with no violations related to air pollution control.

Waste Gas Treatment

The main types of air pollutants at TSC are acidic and alkali waste gases and VOCs. TSC prevents pollution using treatment equipment and processes corresponding to the type and properties of waste gases. Acidic and alkaline waste gas, as well as VOCs, are effectively managed through various control equipment, including acid and alkaline scrubbing towers, and zeolite rotor incineration systems, while continuous monitoring is conducted using the gas chromatography flame ionization detector (GC-FID) system to ensure that the control equipment operates efficiently and meets regulatory standards.

© Copyright 2026 Taiwan Semiconductor Co., Ltd.

- Cookie Settings

- Website Feedback

- Privacy Policy

- Terms of use

- Terms & Conditions