Revolutionizing 24V and 48V Powertrain DC-Link Protection with the LTD7S24CAH

Today’s world is moving at a fast pace and so is the increasing need of Power Management, Efficiency and Reliability in Industry. Be it Automotive sector or Industrial sector, developers and manufacturers are putting their heads together to find a solution that is more reliable, cost effective and budget friendly. It has always been the prime focus of the designers to adapt to modern technologies and solution which aims at BOM cost reduction.

One of these solutions are now provided by Taiwan Semiconductor in the form of a 24V LTD7S24CAH TVS device. This device is capable enough to provide lower clamping voltage and giving the designers a chance to lower the specification of other components especially in 24V-48V Motor Control systems or Power Train solution (DC Link). Using this low clamping TVS device instead of standard device will enable the designer to effectively reduce the BOM cost of the overall design. Let’s discuss this with the used case of DC Link capacitor.

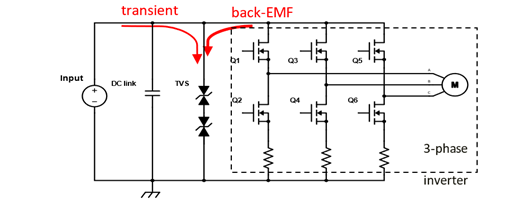

In the ever-evolving world of automotive and industrial power electronics, 24V and 48 V power train systems have become a standard for enabling fuel efficiency, high-power and precise motor control and mild hybridization. At the very centre of this resides a DC Link capacitor — a critical component that stabilizes voltage between power stages, mitigates ripples, and enables efficient power conversion.

However, this component is also highly vulnerable to voltage spikes and transient currents, which can severely degrade its performance or cause terrible failure. Traditionally, protecting the DC-Link required a combination of large electrolytic capacitors, and complex snubber networks — all contributing to higher BOM (Bill of Materials) cost and board space usage.

Taiwan Semiconductor’s latest innovation, the LTD7S24CAH Super Clamp TVS diode, provides a breakthrough in this regard. Engineered specifically for harsh environments like 24V (Using one LTD7S24CAH) and 48V (Using two LTD7S24CAH in series) in automotive and industrial applications, the LTD7S24CAH delivers exceptionally low clamping voltage while ensuring high reliability and simplified circuit design.

Low Clamping Voltage = High Protection

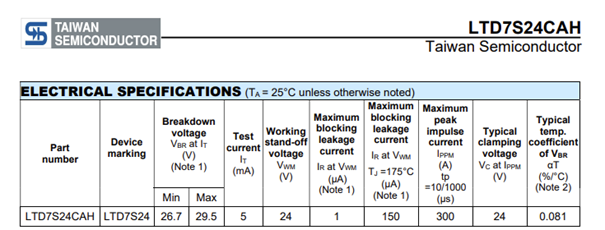

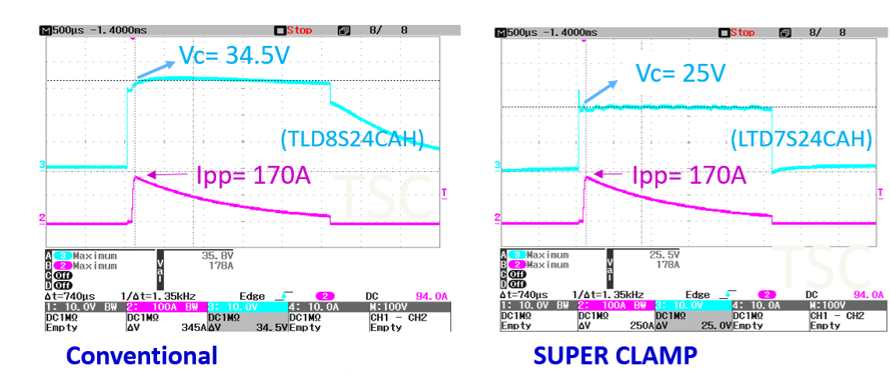

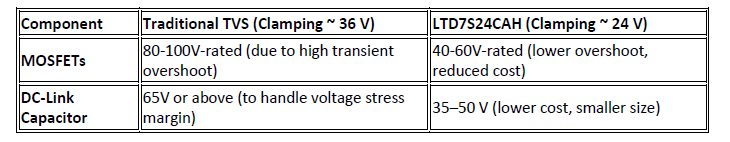

The standout feature of the LTD7S24CAH is the typical clamping voltage of just 24V and peak impulse current capability of 300A (tp = 10/1000 µs). This low clamping behaviour significantly reduces stress on adjacent power components, particularly in the example of DC-Link capacitor protection and MOSFETs, extending their operational life and enabling the use of lower-cost components.

Despite their compact size, snapback TVS devices can handle substantial surge currents, offering robust protection against manmade or naturally occurring high-energy transients.

Fig. 3 shows the behavior distinguishing a snapback TVS device from a conventional bidirectional TVS diode. When a transient voltage surge occurs, the device clamps the voltage to a predetermined threshold. As the current increases, the device enters a “snapback region” where the voltage decreases to a lower, more stable level to provide enhanced protection. As the current approaches zero, the snapback TVS device returns to a high impedance state, resetting for the next transient application.

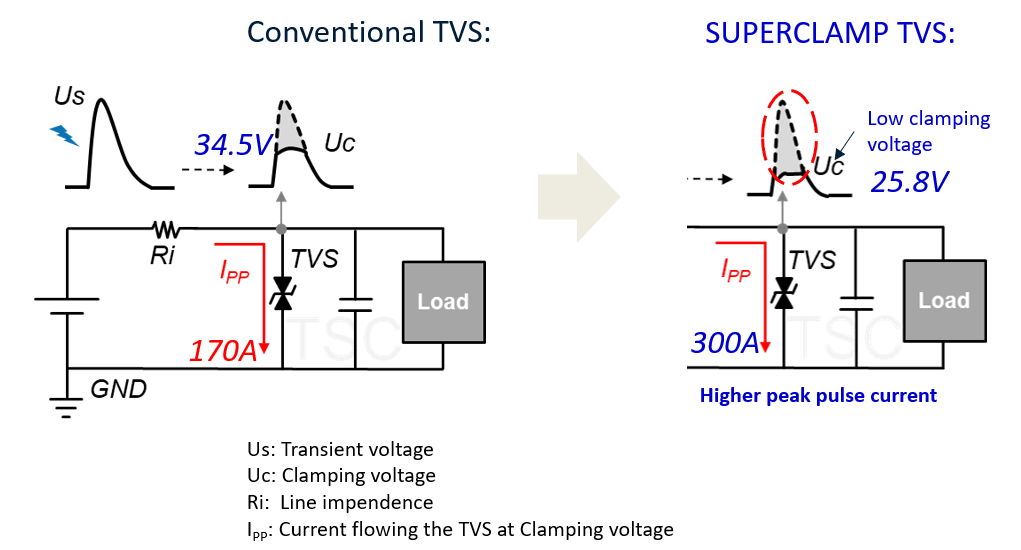

Design Optimization: Standard TVS vs Super Clamp LTD7S24CAH

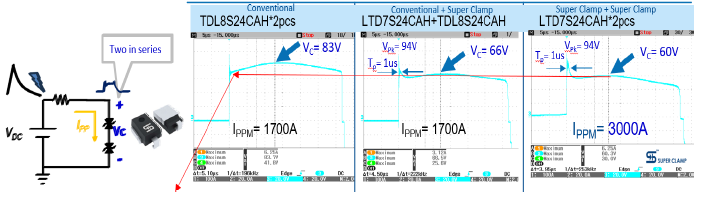

Let’s have a look at the different combination of TVS for 48V system.

As can be seen in figure 4, two Super Clamp TVS, connected together for 48V system are exposed to 8/20us pulse. The spike is reduced slowly from 60V (worst case due to breakdown voltage) to around ~50V. Let’s compare a typical design using a standard TVS diode vs a new design optimized with LTD7S24CAH.

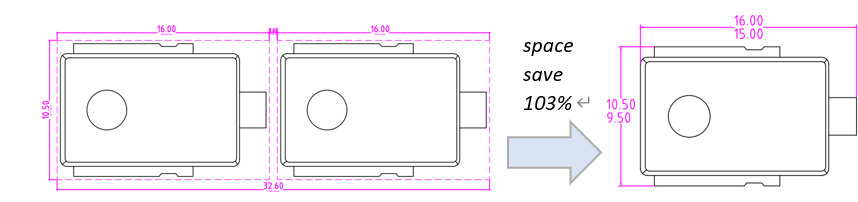

Additionally, the Super Clamp series can handle much higher pulse currents within the same package size i.e., ~300A in DO-218AB versus 170A for traditional TVSs. In other words, under the same voltage conditions, a single Super Clamp device can deliver the current capability equivalent to that of two conventional TVSs. This allows for significant PCB space savings when using Super Clamp.

Result: Designers can confidently replace high-voltage, bulky components with smaller and more cost-effective ones without compromising protection. The LTD7S24CAH offers immediate PCB and BOM cost savings while simplifying thermal and mechanical design considerations.

Conclusion: A Practical Solution for Smart Design

Taiwan Semiconductor’s LTD7S24CAH Super Clamp TVS diode brings a smart, application-specific solution to 24V and 48V, Motor Control and Power Train designs. It directly addresses the protection challenges of the DC-Link capacitor and empower designers to simplify circuits, reduce component stress, and lower overall BOM costs — all without compromising performance or reliability. With Super Clamp TVS, there are abundant benefits for designers including a few like,

- Reduce maximum required MOSFET voltage specifications.

- Reduce maximum DC-Link Capacitor voltage ratings.

- Lower specifications lead to a compact size, saving on PCB space as well.

- Improve overall system reliability.

- Overall leading to BOM Cost Reduction.

Author’s Profile

Muhammad Ahad Rafiq

Taiwan Semiconductor Senior Field Application Engineer

Products